I use a brand new stock set of variator because my old modified variator and the sliding boss already worn. I ordered DP sliders instead of modifying another set of stock variator because the stock sliders weren't too good for performance. They will flattened for as short as 5000km and reduce top speed gradually as they further worn. And to modify the grooves again....uuugh I don't think I have the patience anymore. I thought why not try DP sliders as they're cheap and easy to get.

My first try was to install all the sliders as is, no mods, stock set of variator/ramp/pulley. The stock set will give you 118-119km/h tacho reads. DP sliders instantly gives you 122km/h tacho (with my slightly worn belt). The engine revs higher as DP is 15gr compared to stock 18gr. The bike pulled harder and faster and didn't suffer reduced top speed like using round 15gr rollers. But there was an interesting "over upshift" feels started at 60km/h. I discovered later that this was caused by the rotated sliders. Yes, the sliders not only move outwards but they rotate at some point. It feels like when you shift from 3rd gear to 5th gear, skipping the 4th. But I think the cure is easy, just ride it often around that speed range and the sliders steep transition (between 1st flat face to 2nd flat face) will eventually worn down, gives you smoother transition. Or you can sand/file it.

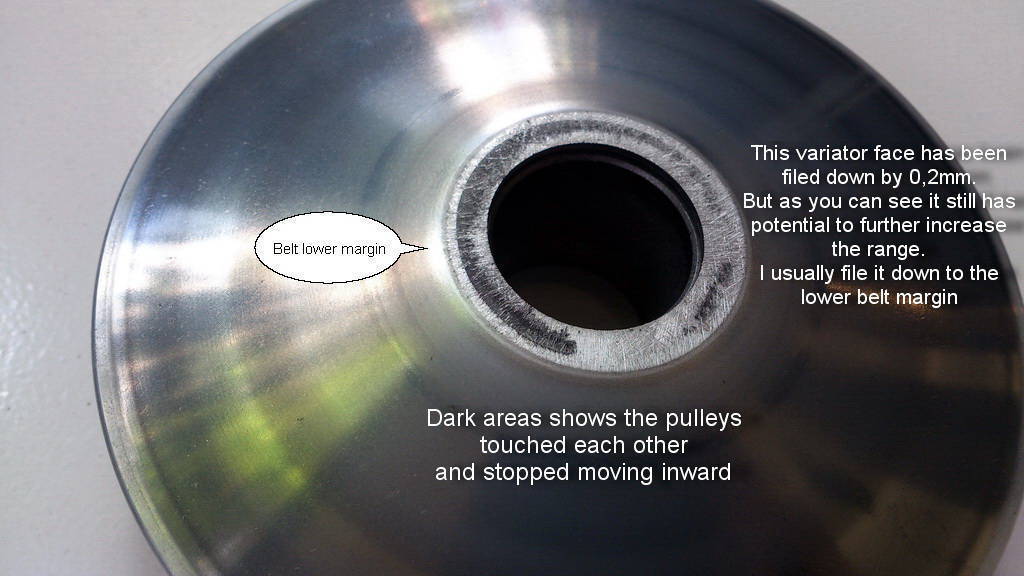

I was happy to see that the variator and the left pulley touched each other, that means more gear ratio potential!!! I reduce the variator thickness using file by 0,2mm and the speed went up to 125km/h (static-tacho). Stock variator lefft about 4,5mm untouched high margin, after filing down 0,2mm it was reduced to 3mm. Yes, now I just use crude file instead of milling machine after I found out that the mating surface between variator and the pulley are very soft and after several "touchy" runs will perfectly mated each other.

Now, I'm still reducing the variator thickness to it's maximum potential. I'll post the result when I have the time.